OUR CORE COMPETENCES ARE THE KEY TO YOUR SUCCESS

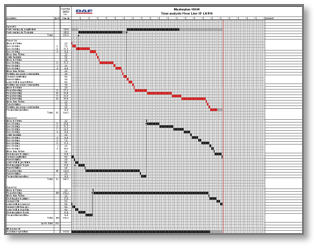

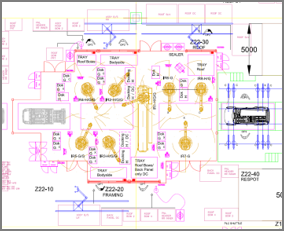

The development of a product, its production and the planning of the necessary production lines are our passion, and have been for more than 40 years. The networking of product development and production engineering even in the earliest planning stages is what makes us and our clients so successful. The independence of plant and machine manufacturers guarantees our partners technically optimal and cost-effective overall solutions.

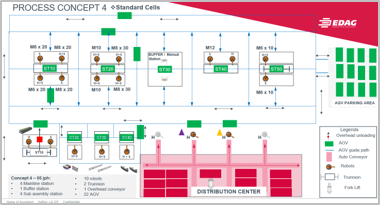

Whether you just want to optimize part of your production or want to plan and implement a completely new factory: We accompany you in all phases of planning and of the engineering concept, but can also accept responsibility for general planning. We therefore stand out from many other vendors due to our implementation expertise, because we not only plan together with our clients, but accompany them up to realization of the project. On request we also manage building construction, approval and media planning, and manage the planned production as a turnkey project.

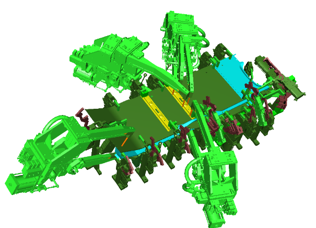

General Assembly Planning

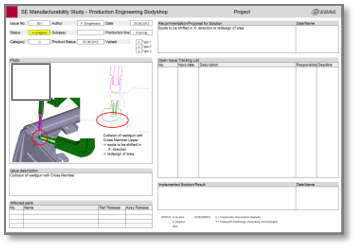

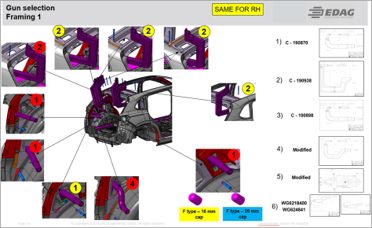

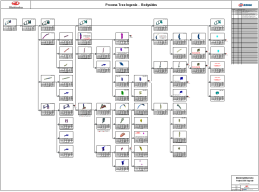

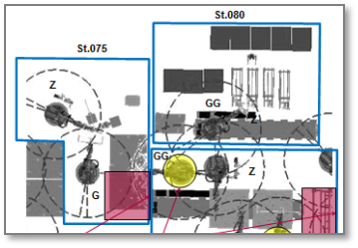

Planning Body Shop (BIW)