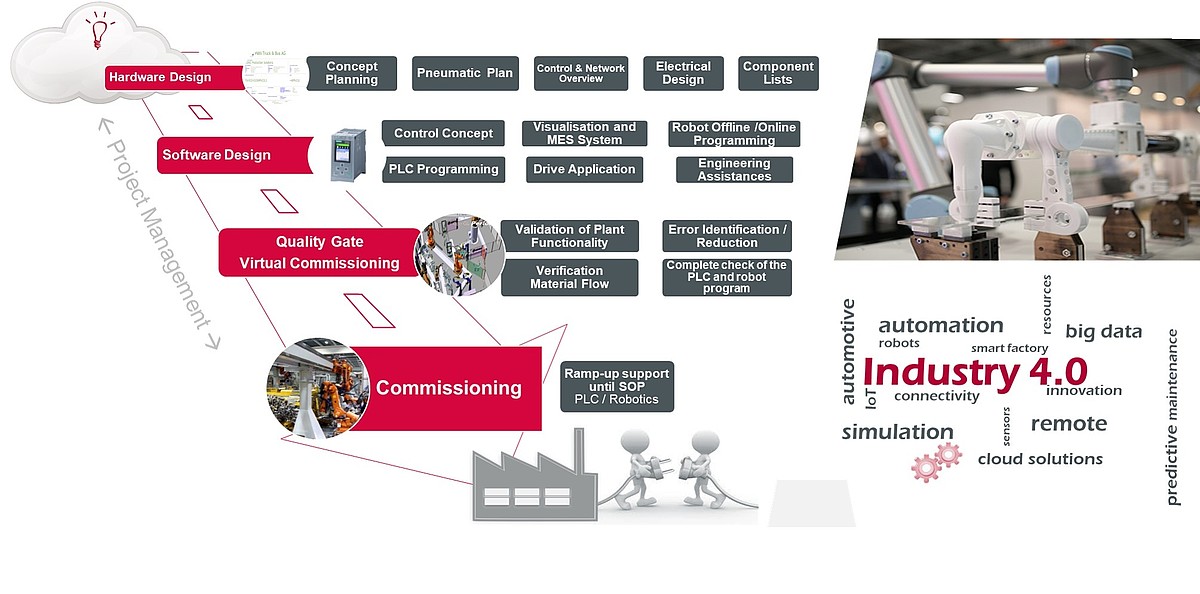

AUTOMATION – ACROSS ALL DEPARTMENTS AND TRADES WITHOUT INTERFACE LOSSES

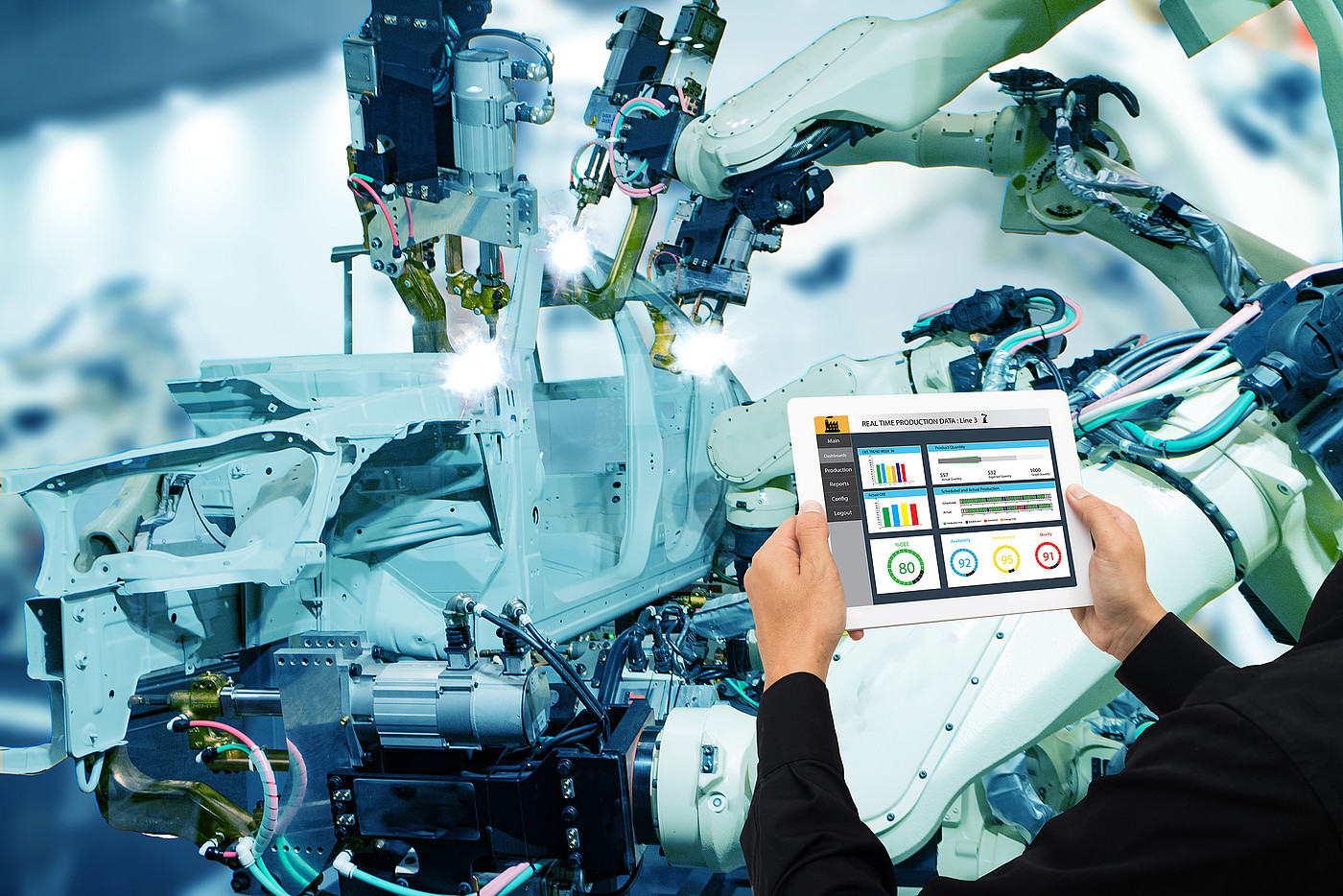

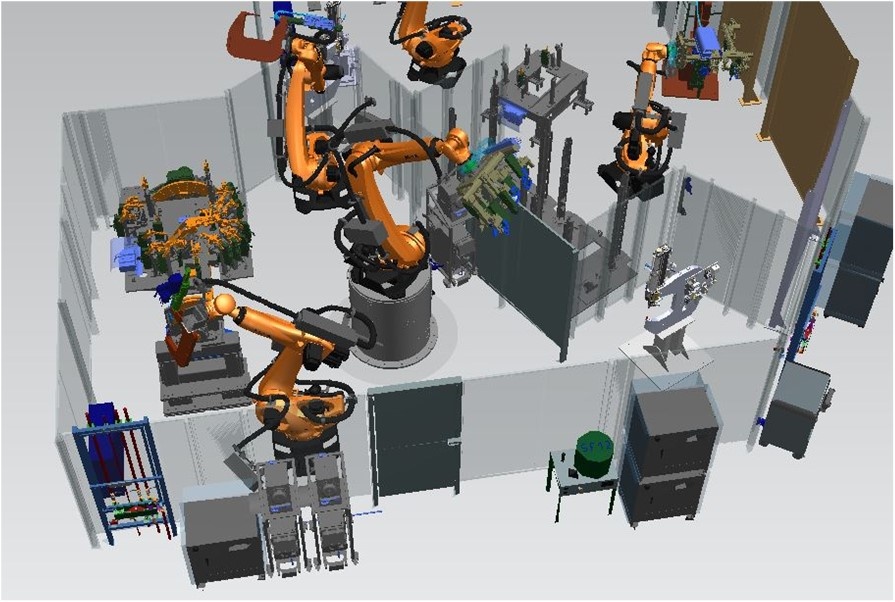

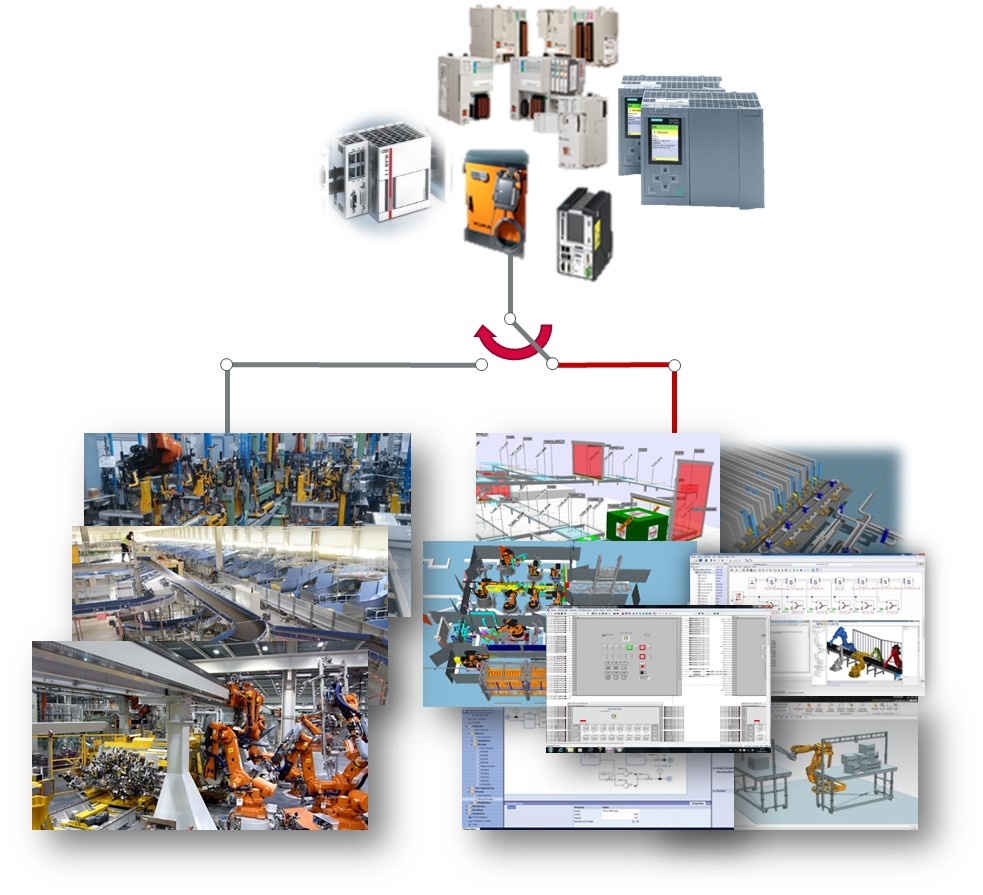

Automation is the art of manufacturing products with a minimum of manual intervention, at high quality and at low cost. All departments/trades should therefore be perfectly coordinated with each other. EDAG PS achieves this high level of automation through the use of modern innovative tools, experience, the technology of the digital factory, and virtual commissioning.

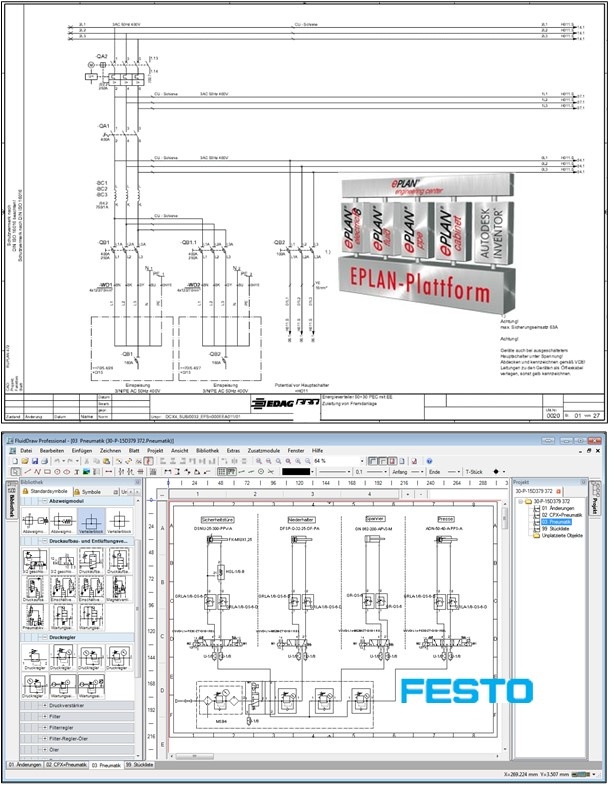

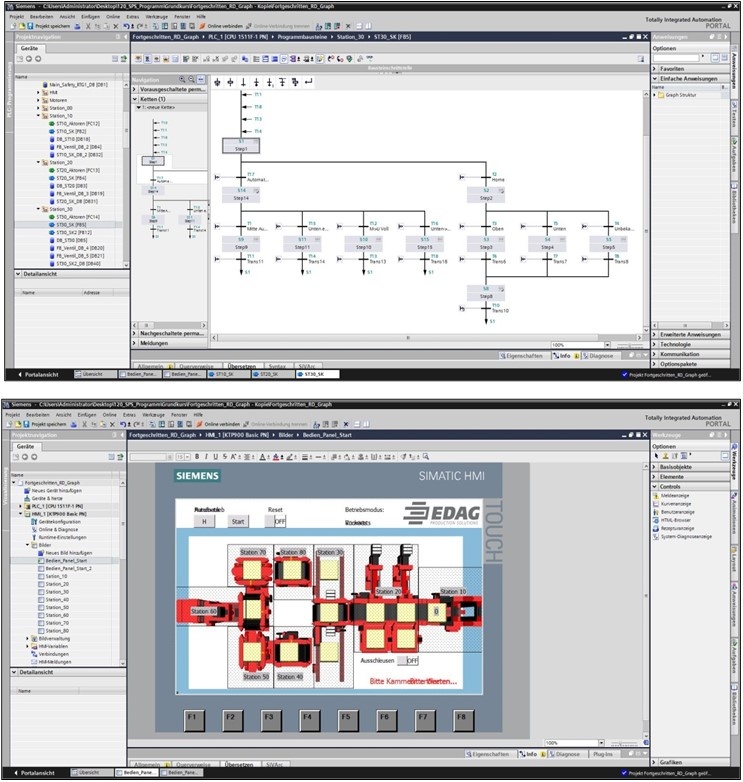

PLC programmers with expertise in Software Design for a wide range of application

and complete automation all automotive production especially BIW

Our Services

Our know-how in the systems of all common robot and application technologies and OEM standards is the ideal basis for your robotics topics.

Our Services

Offline Programming (OLP) with RCS

Online Programming

Support for virtual commissioning

In connection with the actual commissioning on site until SOP

Benefit