We are in the middle of the digital era. Whether private or working life, whether shopping, travelling, falling in love, whether planning, constructing, archiving: we are networked, we stay online, we produce data and we process data. That’s our reality of life.

Unlike certain private or creative areas, where we sometimes want less “Always On”, in many segments of the economy and consumer goods production it can’t be enough. Networked right down to the last LED, you can not only keep control of all functions and features, but also save resources and money.

Let’s roll down our shirtsleeves.

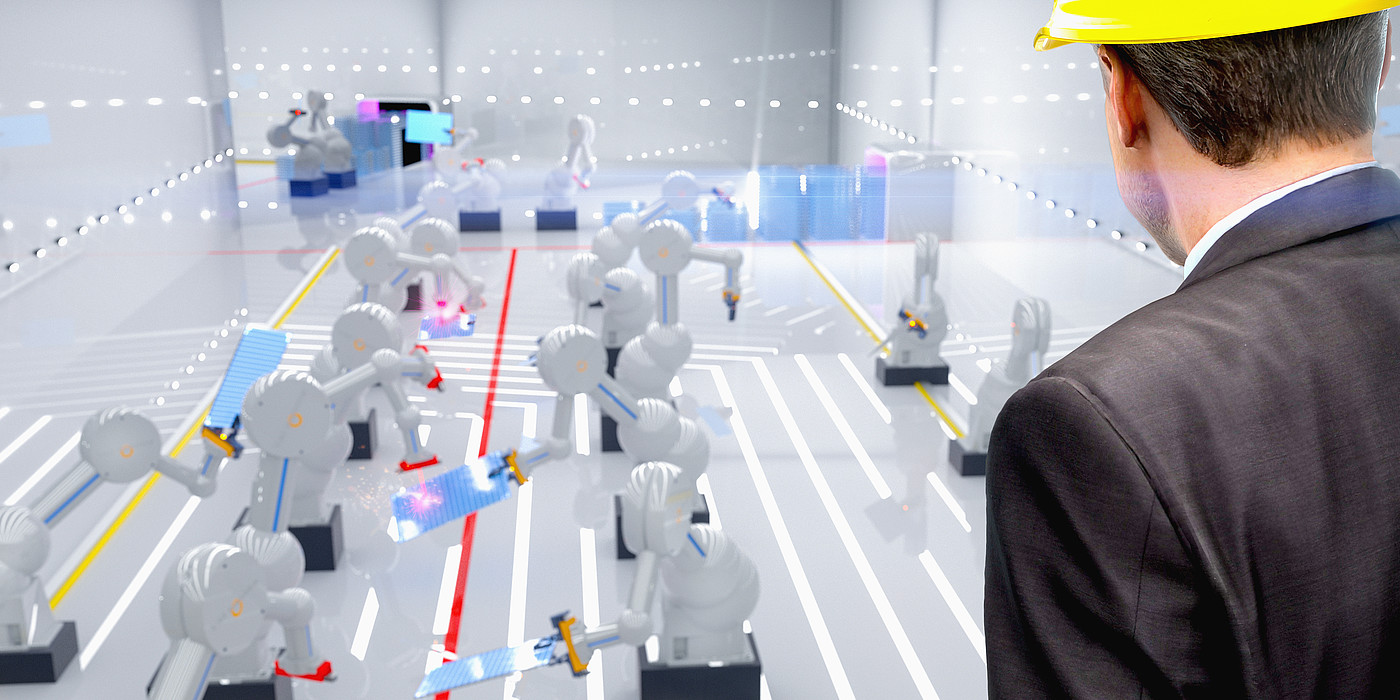

In virtual commissioning, digital technologies are taken to their performance limits.

First, the characteristics of the plant periphery of a production system are simulated. The virtual model of the system generated for this purpose is of such detail, that all software components can be tested and optimized for later use on the actual production system.

Here, the great potential lies in the spacial relocation. On-site activities can be shifted to the office where they can be processed on time without disruption. This minimizes the danger of real plant technologies being damaged by software errors.

Even with tightly scheduled deadlines the system´s downtime can be shortened as much can be tested on the virtual system model in advance.

This enables complex machine processes, any special funtions the system is required to have, interface definitions and visualtisation-related matters tob e programmed and coordinated with the customer in advance.

Independent for the benefit of the customer

Among the many virtual commissioning software environments available on the market, it is difficult to find the one that is perfectly customized to user needs.

At EDAG PS, we have the advantage of being able to choose software freely from the market, in line with customer needs. Our wide-ranging experience in automation and mechatronic engineering enables us to master projects with a reliable and proven team.